Today’s globally competitive business environment expects nothing short of perfection and ABI’s management team ensures that there is no room for error in terms of either quality or global practices. ABI maintains a scalable Quality Management System for effective management of business operations. This system gives the organization a focal point for promoting best practice and continuous improvement in accordance with the defined quality policy.

A Commitment To Quality

With ISO 9001:2015 Quality Certification, ABI is focused on personal and team management. As an organization, we believe in the value of education and training rather than policing. Our training programs empower our workforce with the knowledge, confidence, and motivation to take responsibility for delivering superior quality products on a daily basis.

Policy

Accurate Ball Industries is constantly looking to meet and exceed its customers’ expectations and has rigid standards of process and quality. The selection process starts right from the arrival of raw material until the steel balls roll out of the factory. Our experts chemically analyze and test every coil of wire or a piece of the bar for its physical properties before it is approved. It is ensured that forgings are uniform in diameter and acid etched. After heat-treatment, the whole lot is checked for hardness and microstructure. After lapping, every lot is checked for surface defect and perfect roundness is ensured using precision instruments.

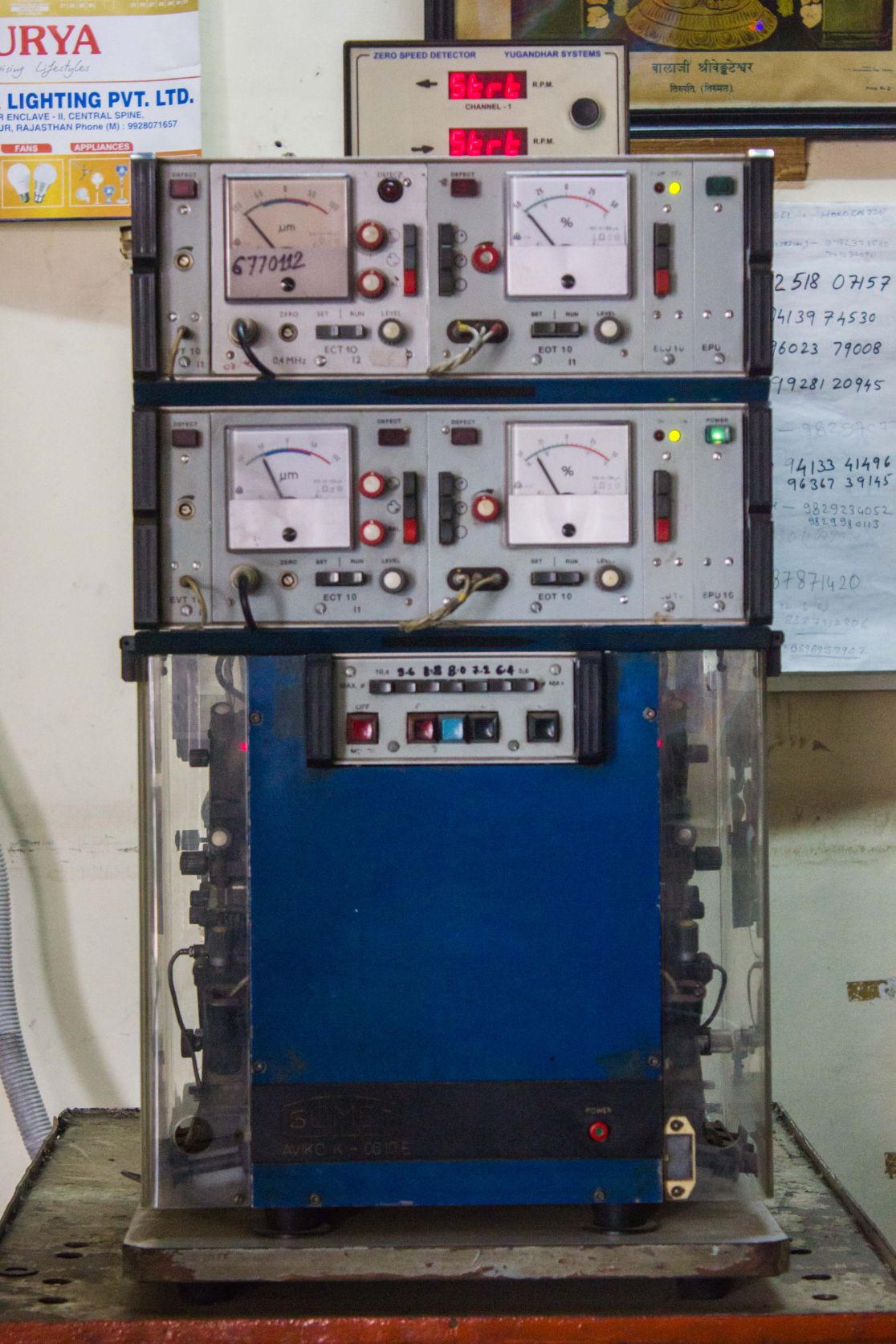

Each ball is visually inspected by our quality control personnel and then is passed through censor for 100% dimensional accuracy. The balls are then finally packed, after giving them anti-corrosive coating to make them rust-proof.

Our employees relentlessly check and recheck to make sure no human errors or defects are overlooked. This meticulous quality control process is followed to ensure consistent quality, competitiveness and guaranteed customer satisfaction.

Waviness testing

Tally Surf

Tally Round

Microscope

Metallurgical Microscope